“Calyxt offers customers the opportunity to target a broad range of plant biomolecules and applications produced through a highly sustainable process and within a highly efficient timeframe,” says Michael Carr, President and CEO at Calyxt.

The company – which previously focused on gene editing, plant breeding and trait development for agriculture end markets – announced its expansion into nutraceutical, cosmeceutical, pharmaceutical, advanced materials and chemical industries as part of an overall strategy to meet customer-driven demand.

At the intersection of finite resources and sustainability

Industry’s growing innovation needs, the company says, represent a “significant plant-based synthetic biology opportunity” to “revolutionize the way the world uses plants” at “the intersection of finite resources and sustainability”.

Carr explains that the new Calyxt strategy responds to customer demand for more sustainable alternatives to existing compounds and the need to reduce carbon footprints.

“By leveraging our proprietary PlantSpring technology platform with our newly commissioned pilot bioreactor, the BioFactory, Calyxt has the pieces in place to advance plant-based synthetic biology solutions for important target customers and end markets to help those groups produce more sustainable products toward meeting their corporate sustainability targets,” he says.

The company expects to be able to rapidly prototype and produce complex plant-derived compounds without the need for outdoor cropping systems and the associated sustainability challenges.

Unleashing the power of plants

PlantSpring is Calyxt’s proprietary “innovation pipeline”, which takes customers through the development process from design and engineering through verification and learning.

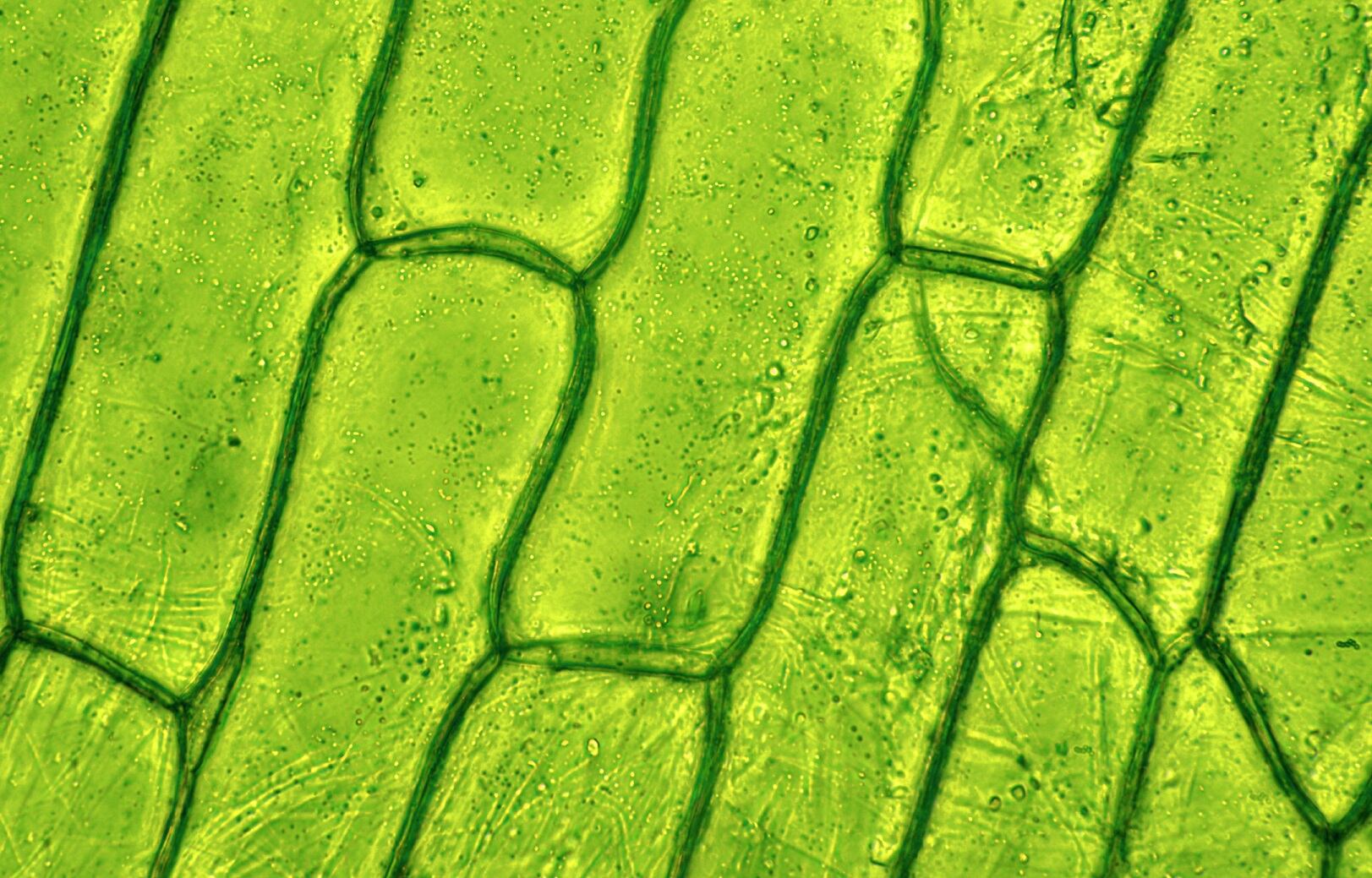

“By using PlantSpring, Calyxt is able to unleash the natural capabilities of the plant, the original biological system and makes available a platform for harnessing chemistries from rare and undomesticated plant species in a more robust and sustainable manner,” says Dr. Travis Frey, Chief Technology Officer at Calyxt.

“Calyxt’s scientists are experts at engineering plant metabolism, which includes enabling the plant cells to produce more or less of certain chemistries, or novel chemistries, that may be unique to plants.”

Most recently, the platform was augmented with artificial intelligence to drive down production cycle times, leveraging data gained through the development process to enhance and accelerate learnings for production of the target compound.

Moving production indoors

The BioFactory manufacturing facility is being developed to work together with PlantSpring to produce plant biomolecules at scale and sustainably, with expected delivery of the first pilot bioreactor in early 2022.

“The scaled production of these biomolecules through our BioFactory will be vital for our customers because it will provide them with more sustainable-sourced materials for their own manufacturing processes,” Frey explains.

With the addition of the Biofactory, Calyxt expects to produce compounds at higher yields and throughputs on a per-unit basis, expanding production methods from solely outdoor agriculture systems to include controlled environments.

“Because it does not use fermentation, we expect fewer of the sustainability challenges associated with other indoor systems, including potentially lower levels of off-gasses, reduced water demands and lower energy requirements,” Frey says.